Introduction:

Transformer cooling methods are used based on transformer size, application, and load requirements.Transformers generate heat due to energy losses (copper and iron losses), and efficient cooling is essential to maintain performance and lifespan.

In this article, we explore various transformer cooling techniques, including:

ONAN (Oil Natural Air Natural)

ONAF (Oil Natural Air Forced)

OFAF (Oil Forced Air Forced)

OFWF (Oil Forced Water Forced)

ODAF (Oil Directed Air Forced)

ODWF (Oil Directed Water Forced)

Let’s dive into each method in detail.

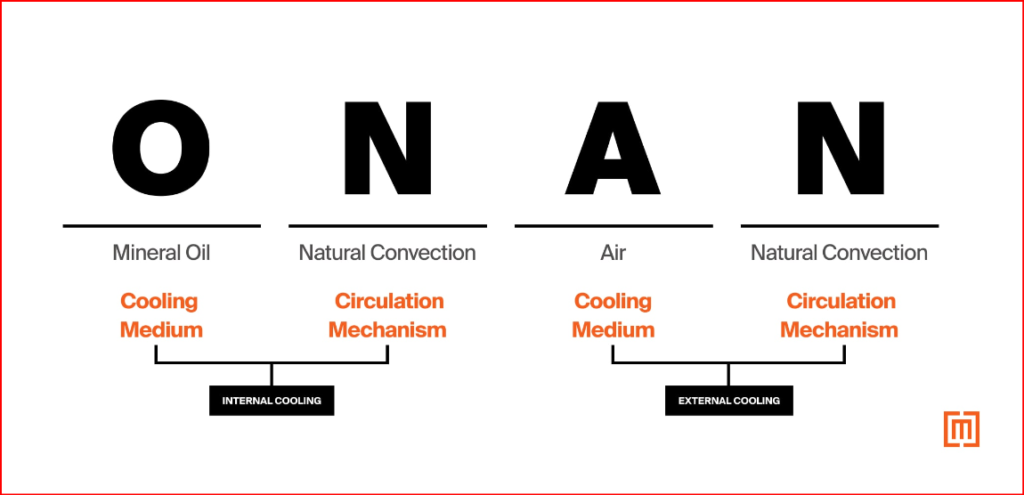

1. ONAN (Oil Natural Air Natural) – The Simplest Cooling System

This is the most basic transformer cooling method, where natural convection cools the oil.

How It Works:

Hot oil rises to the top of the transformer tank, and cold oil replaces it.

The hot oil dissipates heat into the atmosphere through natural conduction, convection, and radiation.

The cycle continues as long as the transformer is under load.

Advantages:

✔ No external power required for cooling.

✔ Simple and maintenance-friendly.

Limitations:

✖ Limited cooling capacity, suitable for small transformers.

2. ONAF (Oil Natural Air Forced) – Enhanced Air Cooling

This method improves cooling efficiency by using forced airflow over the transformer’s cooling surfaces.

How It Works:

Fans blow air over radiators, increasing heat dissipation.

The forced airflow removes heat faster than natural convection.

Allows higher load capacity without exceeding temperature limits.

Advantages:

✔ Better cooling than ONAN.

✔ Suitable for medium to large transformers.

Limitations:

✖ Requires external power for fans.

3. OFAF (Oil Forced Air Forced) – Forced Oil & Air Circulation

Here, both oil and air circulation are forced, making cooling even more efficient.

How It Works:

Oil pumps circulate oil inside the transformer.

Fans provide forced air cooling on radiators.

Faster heat transfer compared to ONAF.

Advantages:

✔ Compact design with high cooling efficiency.

✔ Occupies less space than ONAN/ONAF for the same capacity.

Limitations:

✖ Higher energy consumption due to pumps and fans.

4. OFWF (Oil Forced Water Forced) – Water-Based Cooling

Since water has better heat exchange properties than air, this method is used for high-capacity transformers.

How It Works:

Oil pumps send hot oil to a water-oil heat exchanger.

Cold water flows over the heat exchanger pipes, cooling the oil.

The cooled oil returns to the transformer.

Advantages:

✔ Superior cooling efficiency (water absorbs heat better than air).

✔ Ideal for high-load applications.

Limitations:

✖ Requires a continuous water supply and cooling system.

5. ODAF (Oil Directed Air Forced) – Directed Oil Flow Cooling

An improved version of OFAF, where oil is directed through specific paths in the windings for better cooling.

How It Works:

Oil is forced through predefined channels in the transformer windings.

Enhances heat transfer by ensuring oil flows over hotspots.

Used in very high-rating transformers.

Advantages:

✔ Highly efficient cooling for large power transformers.

✔ Better heat distribution than OFAF.

Limitations:

✖ Complex design and higher maintenance.

6. ODWF (Oil Directed Water Forced) – Directed Oil & Water Cooling

Similar to ODAF, but water is used instead of air for cooling the oil.

How It Works:

Hot oil is directed through winding channels.

A water-cooled heat exchanger removes heat from the oil.

Used in ultra-high-capacity transformers.

Advantages:

✔ Best cooling efficiency for extreme loads.

✔ Suitable for large power stations and industrial use.

Limitations:

✖ Requires a robust water cooling system.

Conclusion: Choosing the Right Cooling Method

The choice of transformer cooling methods depends on:

✅ Transformer size & load (small, medium, or high capacity).

✅ Environmental conditions (availability of water, ambient temperature).

✅ Efficiency & maintenance requirements.

| Cooling Method | Best For | Key Feature |

|---|---|---|

| ONAN | Small transformers | Natural oil & air cooling |

| ONAF | Medium transformers | Forced air cooling |

| OFAF | Large transformers | Forced oil & air circulation |

| OFWF | High-capacity transformers | Water-cooled heat exchanger |

| ODAF | Very high-rating transformers | Directed oil flow + forced air |

| ODWF | Ultra-high-capacity transformers | Directed oil flow + water cooling |

By selecting the right cooling system, transformer efficiency, lifespan, and performance can be optimized.

Which cooling method does your transformer use? Let us know in the comments! 🚀

#Transformers #ElectricalEngineering #PowerSystems #CoolingTechnology